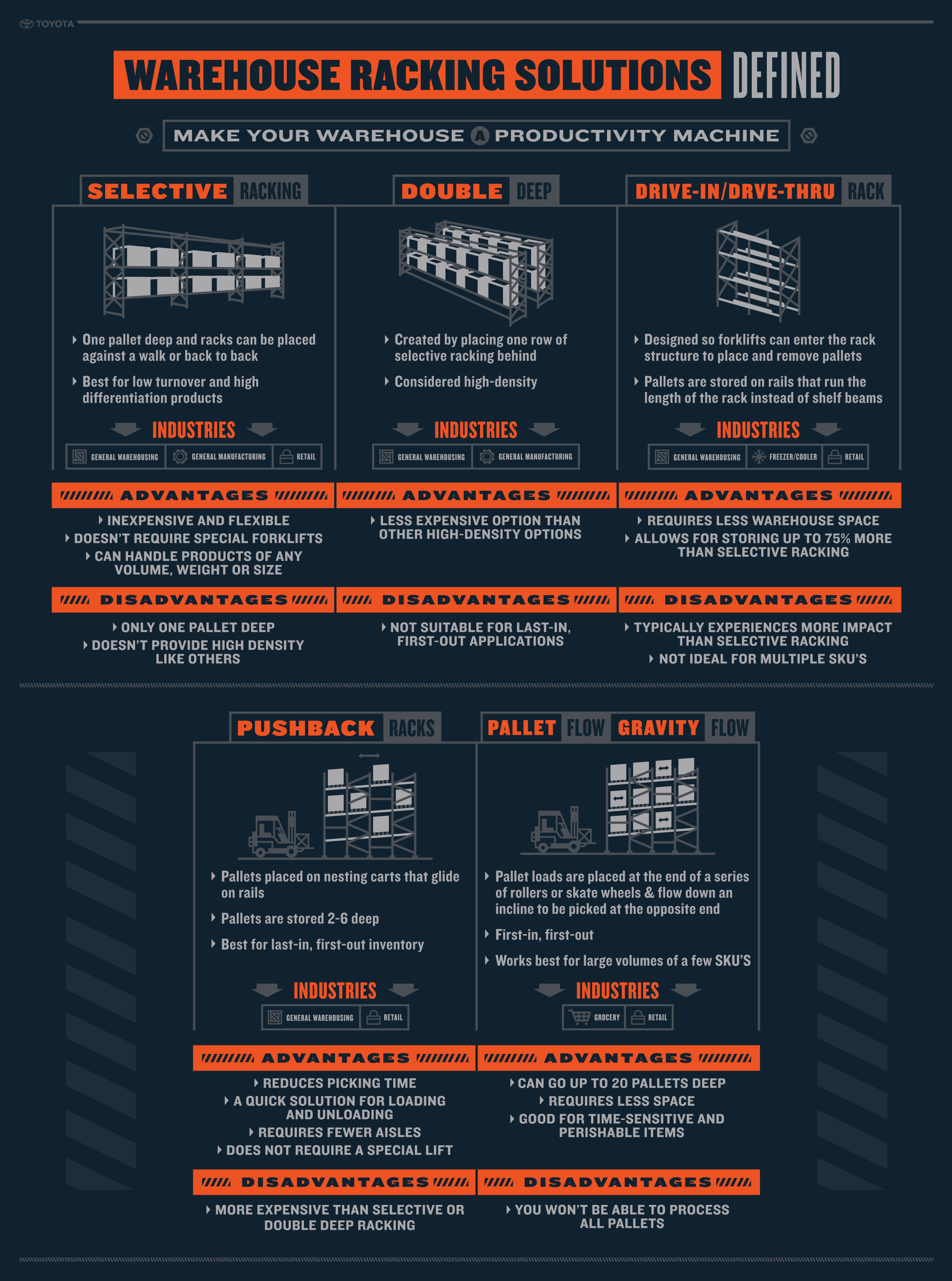

Different types of pallet racks might offer the best solution for your operations – and Dillon Toyota Lift's Warehouse Solutions team can source whichever you need. But how to choose? Here are some basics to help:

Selective Racking – Usually single-deep, this type of racking makes any pallet in the rack system accessible without having to move another pallet.

Pallet Flow Racking – Often referred to as gravity racking, gravity allows the pallet to roll to the front of the system upon loading. When the pallet is removed from the front of the racking system, the pallets behind roll to the front.

Push Back Racking – Used for high-density storage, carts in the rack are stacked on top of each other. The first pallet is loaded from the front and sits on the top cart. When the second pallet is loaded, it pushes the top cart with the first pallet back, granting access to place the new pallet on the second cart.

Drive-In Racking –Used to store a high number of SKUs, forklifts drive into the racking system to move a pallet. This type of pallet racking system is cost-effective by maximizing storage space.