Your business is growing and you either need to expand your current warehouse or build a new warehouse to support your growth. Sounds like a good problem to have! At least, until you have to decide what type of pallet racking system you need to install. In its simplest form, a pallet racking system is a material storage system. Pallet racking helps you stay organized within your warehouse and better manage you inventory. Choosing pallet racking, however, is not as simple as selecting a pallet rack brand and installing it. There several racking types that help you meet your needs. The type of racking you choose depends on a few criteria:

- How tall the racking needs to be

- What goods will be stored

- What the floor plan will be

- What type of inventory management system makes sense for your product and operation

- What types of forklifts you currently use or forklifts you intend to switch to

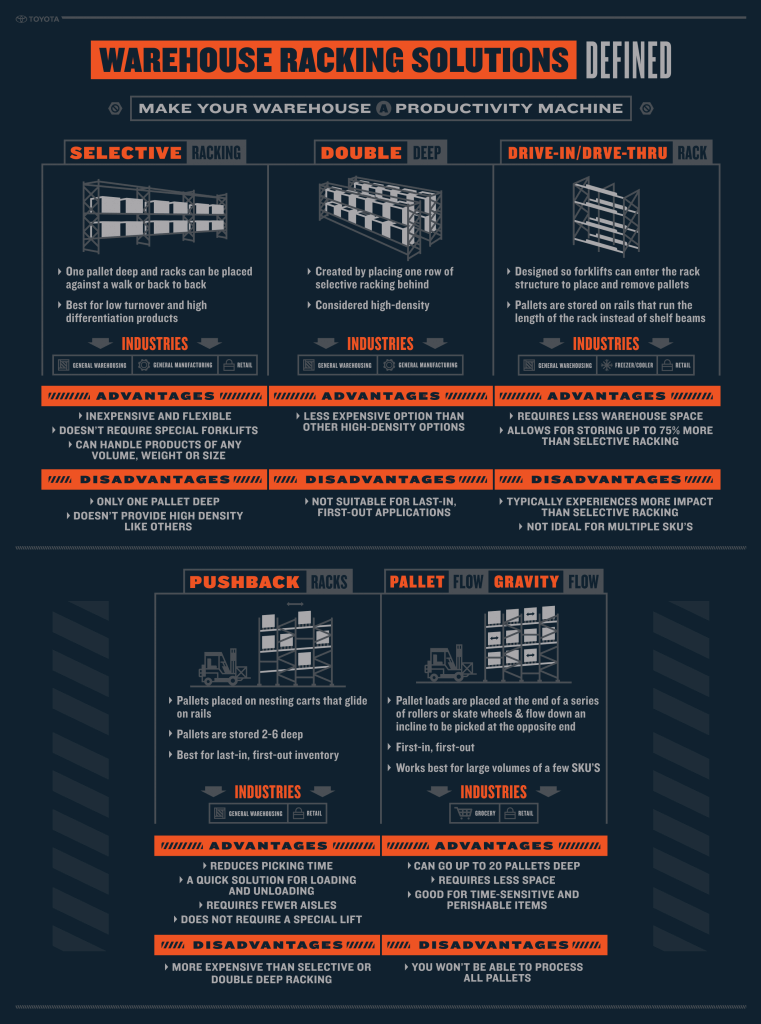

Selective racking systems are some of the most common and widely used racking systems, mainly because they are less expensive and easier to install than other, more specialized racking systems. Selective racking is great for warehouses that store a large amount of stock keeping units (SKUs). Selective pallet racking is usually a single-deep pallet rack. This type of racking makes any given pallet in the rack system accessible without having to move another pallet.

Types of Pallet Racking: Cantilever Racking

Cantilever Racking systems are used to store items that cannot be easily stored on pallets. Warehouses that use cantilever rack, usually store longer and heavier items to be stored horizontally across multiple arms (like lumber or steel pipes). Pallet racks, on the other hand, have vertical uprights that limit the length of stored items. This is the primary difference between cantilever racking and pallet racking.

Pallet flow racking systems are also referred to as “gravity flow” racking systems. Pallet flow racking systems are best suited for the first-in, first-out (FIFO) inventory management methodology. When you load a pallet from the loading aisle and onto the lane rollers, gravity allows the pallet to roll to the front of the system. When the pallet is removed from the front of the racking system, the pallets behind roll to the front of the lane. Pallet flow racking allows for high-density storage while maintaining FIFO. Some pallet flow racking systems may hold up to 20 pallets deep in one lane, minimizing the number of aisles needed to store items while maintaining efficient inventory turnover.

Types of Pallet Racking: Push Back Racking

Push back racking systems is another high density storage option, with the ability to store up to six pallets deep on either side of an aisle. There are usually three carts stacked on top of each other. The first pallet is loaded from the front in a push back racking system and sits on the top cart. When the second pallet is loaded, it pushes the top cart with the first pallet back. Push back racking gives you higher density storage than selective racking systems, while allowing you more selectivity with storing items than other types of racking, meaning you can store more SKUs.

Types of Pallet Racking: Drive-In Racking

Drive-In racking systems are great for storing large volumes of just a few SKUs and can also be configured to manage inventory with FIFO or last-in, first-out (LIFO). With drive-in racking, the forklift literally drives into the racking system to move a pallet. This type of pallet racking system is cost effective by maximizing the amount of storage space in your warehouse.

Choosing between these types of racking systems will depend on the various goals of your operation and the relevant inventory data like volume and throughput. No matter your decision, always be sure that this racking is installed safely and effectively to increase productivity.

Written By: Kenny Trusnik, Marketing Systems & eCommerce Specialist, Toyota Material Handling, USA